SERVICES

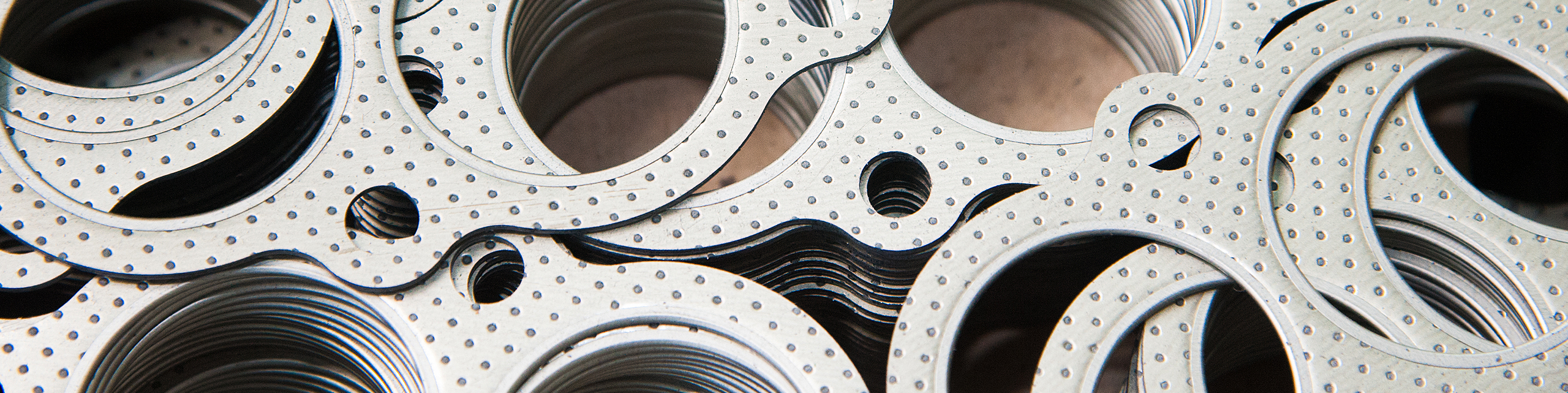

Laser Cut • Flash Cut • Waterjet Cut • Die Cut • Lathe Cut • Kiss Cut • Die Stamping • Garlock Distributor Partner

Value-Added

Gasket Specialties is a value-added company, focusing on made to print production. We can provide:

- Prototype runs

- Part/Kit assembly and packaging

- Part marking – Engraving – Ink marking

- Special packaging

- Barcode labels

- Slitting logs of material to smaller coils

- High volume, repetitive releases for OEM markets

We also support our customer base with providing distribution of required industrial products.

Materials we work with

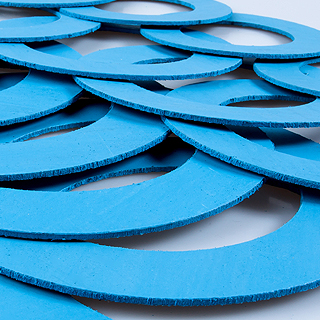

SPONGE RUBBER

- Closed Cell / Open Cell

- Neoprene

- Buna-N

- Silicone

- Viton

- EPDM

- EMI-RFI Shielding

PLASTICS

- Teflon

- Nylon

- Polyethylene

- Polyurethane

- PVC

- Acetate

- Delrin

- Kapton

- Polyamide Film

- Peek

SOLID RUBBER

- Neoprene (Chloroprene)

- EPDM

- Buna-N (Nitrile)

- Santoprene

- Silicone

- Viton

- Pure Gum

- Food Grade (FDA) Elastomers

- Butyl

- Cloth Inserted (CI) Rubber

- Diaphragm Rubber

- Red Rubber

- Masticated Rubber

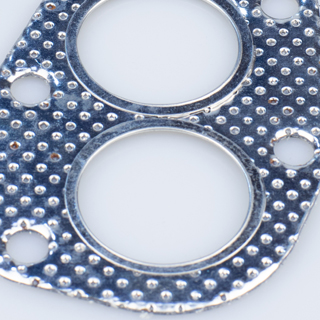

METAL

- Carbon Steel

- Stainless Steel

- Nickel

- Monel

- Inconel

- Aluminum

- Brass/Copper

- Titanium

MISC. MATERIALS

- Graphite

- Compressed Sheet

- Ceramic Fiber

- Cork Rubber

- Fiberglass

- Felt

- Vegetable Fiber

- Beater Sheet

- Phenolic Fiber

- Fish Paper

FOAM

- Poron

- Polyurethane

- Polyethylene

- Filter Foam

- Silicone Foam

SHIM STOCK

- Metal Shim

- Plastic Shim

- Laminated Shim

Gasket Specialties, Inc.

ISO 9001:2015 & AS9100 Certified

Northern California

1143 Marina Way S

Richmond, CA 94804

richmond@gsimfg.com

Tel: (510) 547-7955

SOUTHERN CALIFORNIA

8654 Helms Avenue

Rancho Cucamonga, CA 91730

rancho@gsimfg.com

Tel: (909) 987-4724

NORTHWEST

13035 NE Airport Way

Portland, OR 97230

portland@gsimfg.com

Tel: (503) 257-8816